The soft biscuit mold consists of 4 main parts; side covers, steel cylinder, bronze rings and shafts. Bronze rings are mounted on the cylinder as a single piece and processed concentrically. The next stage is to place the plastic parts on which the motifs will be processed on the bronze. A special technique is applied in placing the plastic parts on the bronze rings. In the last stage, the desired motifs are processed on the plastic part with CNC. The mold design in the hard dough molds is soft biscuit...

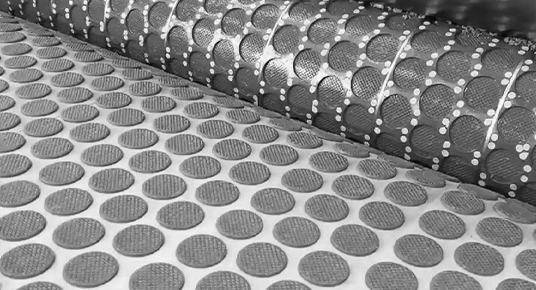

Dough, which is generally rich in fat and sugar, has the feature of being easily shaped and separated from the mold with its slippery structure. Flour quality, temperatures of the inputs, mixing and waiting times are the factors affecting the dough quality and the rotary molding line can be operated efficiently with the care given to these factors. The dough is transferred to the feeding hopper manually or automatically in different weights and then subjected to the shredding process. The shredded dough becomes suitable for rotary molding...

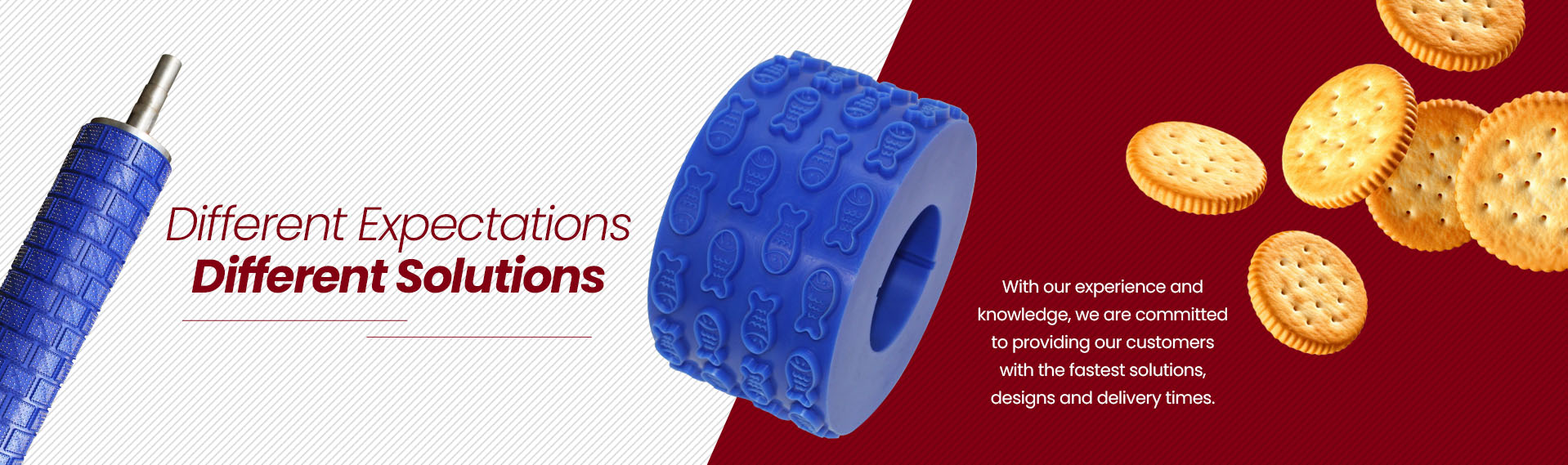

The design of the motif starts upon the request of the customer. The desired visual, size and weight information is given to the design engineer. Depending on whether the product contains simple motifs, a 2-D or, if it is complex, a 3-D rendered technical drawing is shared with the customer. The biscuit manufacturer reviews the preliminary design and checks its compatibility with the desired concept. The other recommended stage is to process the motif into flat plastic or bronze as an example. Thanks to the processed sample, the customer has the chance to evaluate the final product after the oven...

The rotary biscuit machine and biscuit mould should be regularly maintained. A suitable lifting mechanism is required to remove the mould from the rotary biscuit machine. It is recommended to store it on the mould stand against any impact or damage. It is recommended to store it in a dust-free place at room temperature after cleaning. Washing the mould with hot water just before working on the rotary biscuit machine will cause expansion in the bronze ring and increase wear...