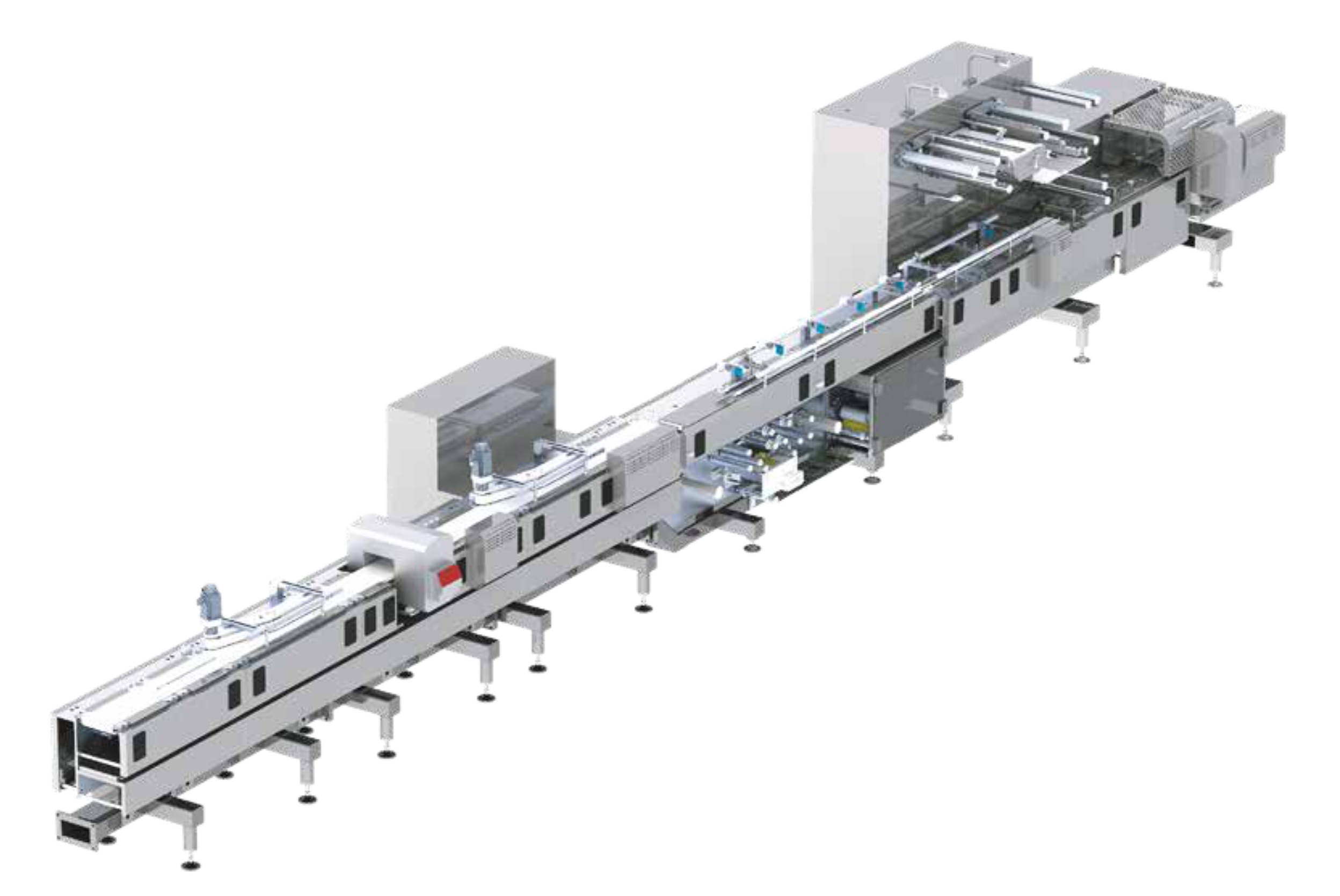

The packaging machine will have a maximum capacity of 400 rpm for cakes. The ambient temperature for coated products should be +20° C.

General Features

• 4 groups of longitudinal gluing discs (1 pulling, 2 gluing, 1 guiding)

• Servo motor driven unwinding roller for precise paper control

• Special, modular jaw group that can be changed according to the product and packaging material.

• Special design that allows the operator to intervene from both sides and provides a hygienic and ergonomic working environment.

• All drive and motion systems and electrical cabinet are placed in isolation in the process line.

• Designed for easy belt change and alignment.

• All settings are made easily and repeatably thanks to the scales.

• There are mechanically adjustable stainless steel scrapers on each belt.

• Easy cleaning is provided thanks to the removable rollers.

• There are stainless steel trays under the conveyors.

• Maintenance and cleaning are simple and quick.

• It provides fast transition for different sizes and shapes.

• Automatic cellophane transfer is available.

• All parts in contact with the product are stainless steel.

• There is 3-dimensional product control and non-conforming products are removed from the system.

• Empty/double/attached packages are removed