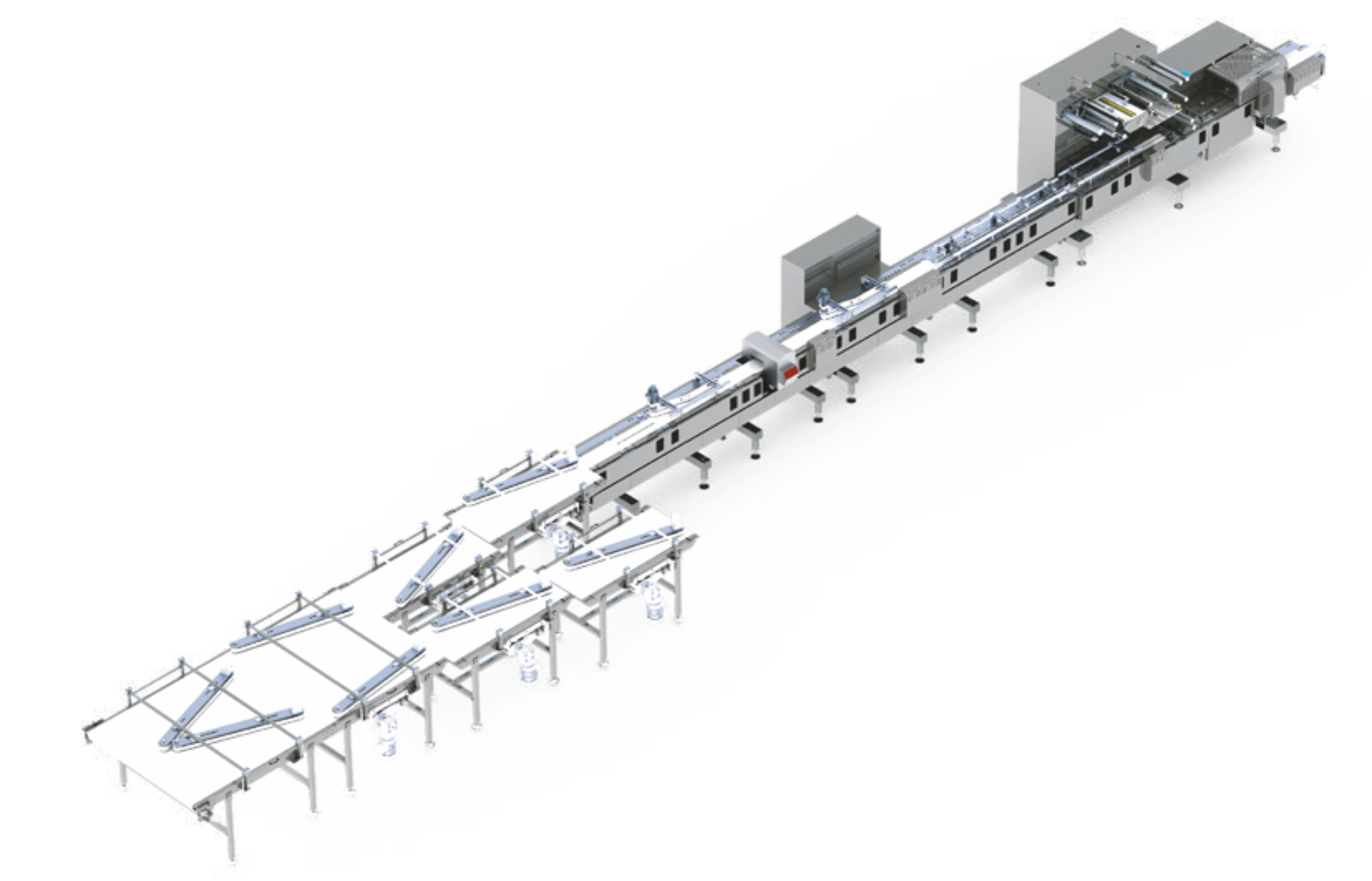

Products arriving on a conveyor in a sequential or scattered manner are divided into many equal channels by means of guides placed on the belt at an angle. Then, the products are aligned under the guidance of one or two driven belts placed at an angle. The channelized product rows pass to the main belt, which has many guiding sections, carrying the products to the packaging machines. The distribution-feeding system is generally used for products coming from the filling or coating line. This system first divides the product flow into channels according to the number of machines to be fed. This is achieved by increasing the speed of the belts equipped with plates with fixed dividers placed on them. The products are then carried to the fast belt where the motor-driven belts are mounted vertically. This ensures that the products arriving in this row are distributed according to the capacity of the relevant machine.

Benefits: