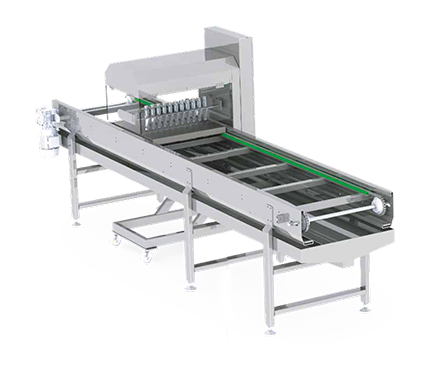

Cake pans need to be lubricated so that they can be easily emptied and the cake does not stick. In this UNIT, which is the first PROCESS of the cake PRODUCTION phase, it is important to SPRAY an appropriate and spread oil to the pans. At the same time, in order to prevent excessive oil consumption and to prevent the oil from burning, oil contact outside the pans should be prevented.

• Nozzle is selected according to the pan placement for effective lubrication,

• Air and oil ratios can be adjusted.

• When it comes to each chamber, it is mixed with air and SPRAYED by receiving a warning from the sensor.

• There is a stainless CrNi heated oil tank.

• Oil flow rate can be adjusted as a whole with INDEPENDENT adjustment.

• The lubrication system is placed in a cabin.

• The return of the blown oil is provided with the vapor absorption system and particle filter.

• The lubrication system is not fixed on the conveyor, but is manufactured independently on a separate chassis.