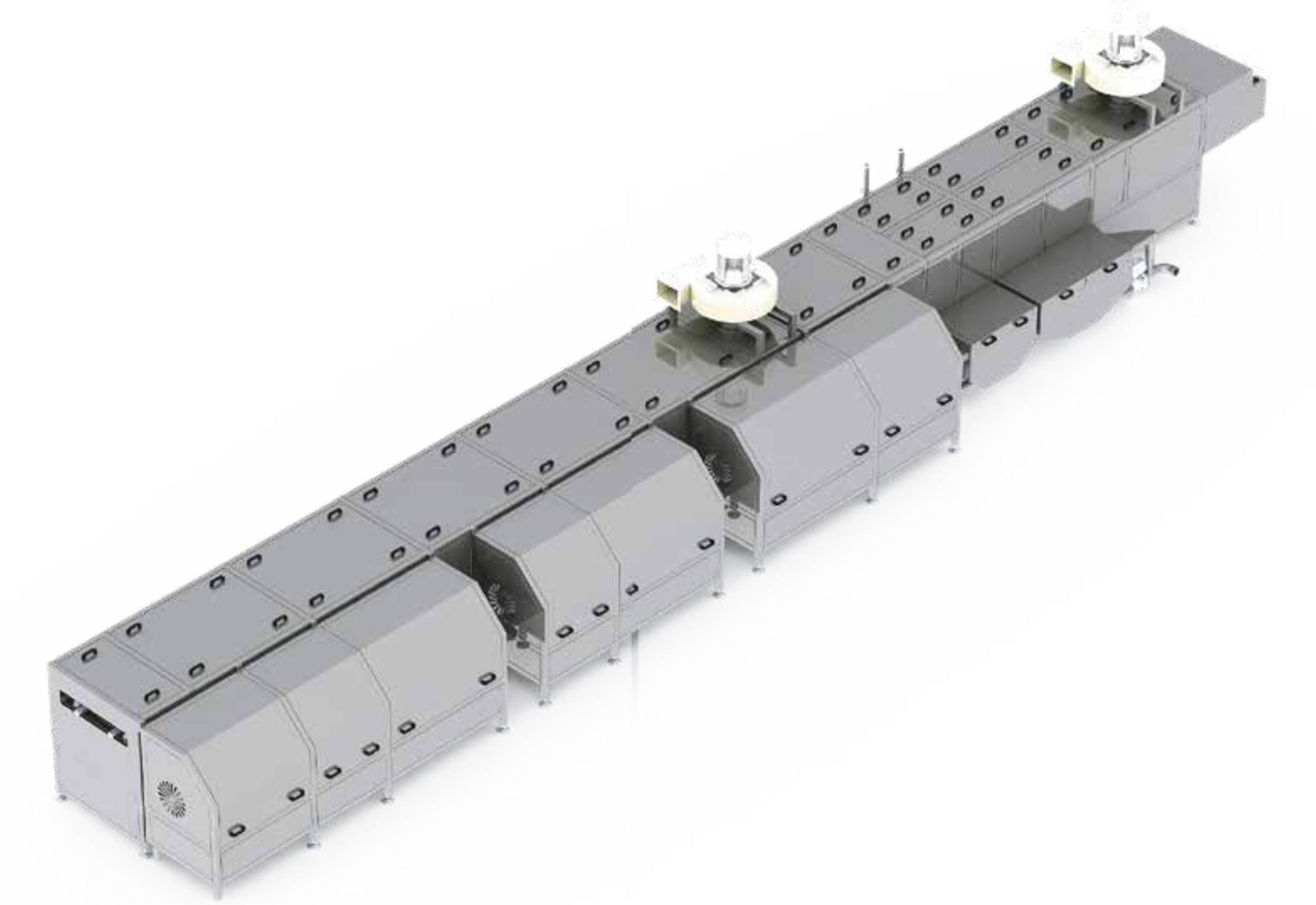

PAN WASHING-DRYING UNIT

It is the unit that provides washing and drying of the pan after the baked cakes are emptied from the pan.

- The pan washing machine is horizontal type,

- The chains used in the washing and drying system are CrNi stainless chains,

- All chassis, bodywork and carriers, slides and installation systems are manufactured from stainless Cr-Ni 304 material,

- The bearing bearings inside the washing are stainless.

- The chain carrying the pans is stainless and narrow-widthed.

- Water with a temperature of 50-60 degrees is used to prevent mold and yeast formation. The heat required for this system is provided by steam,

- There are 2 fans used to remove the steam formed in the machine on our washing and drying system. The chimney system required to remove this unwanted steam from the environment can be made,

- Water circulation is provided by 2 pumps with a power of 11 kW. The water required for the system must be purified.

- The washing system performs homogeneous and stable washing regardless of the changes in the pan form.

- In the drying section, the pans are dried from the bottom and top with 6 high volume chrome blowers.

-

- The pan washing and drying machine is different from the classical facility logic and does not require pan turning units before washing and after drying. In this working logic, the deformation in the pan coatings is eliminated.