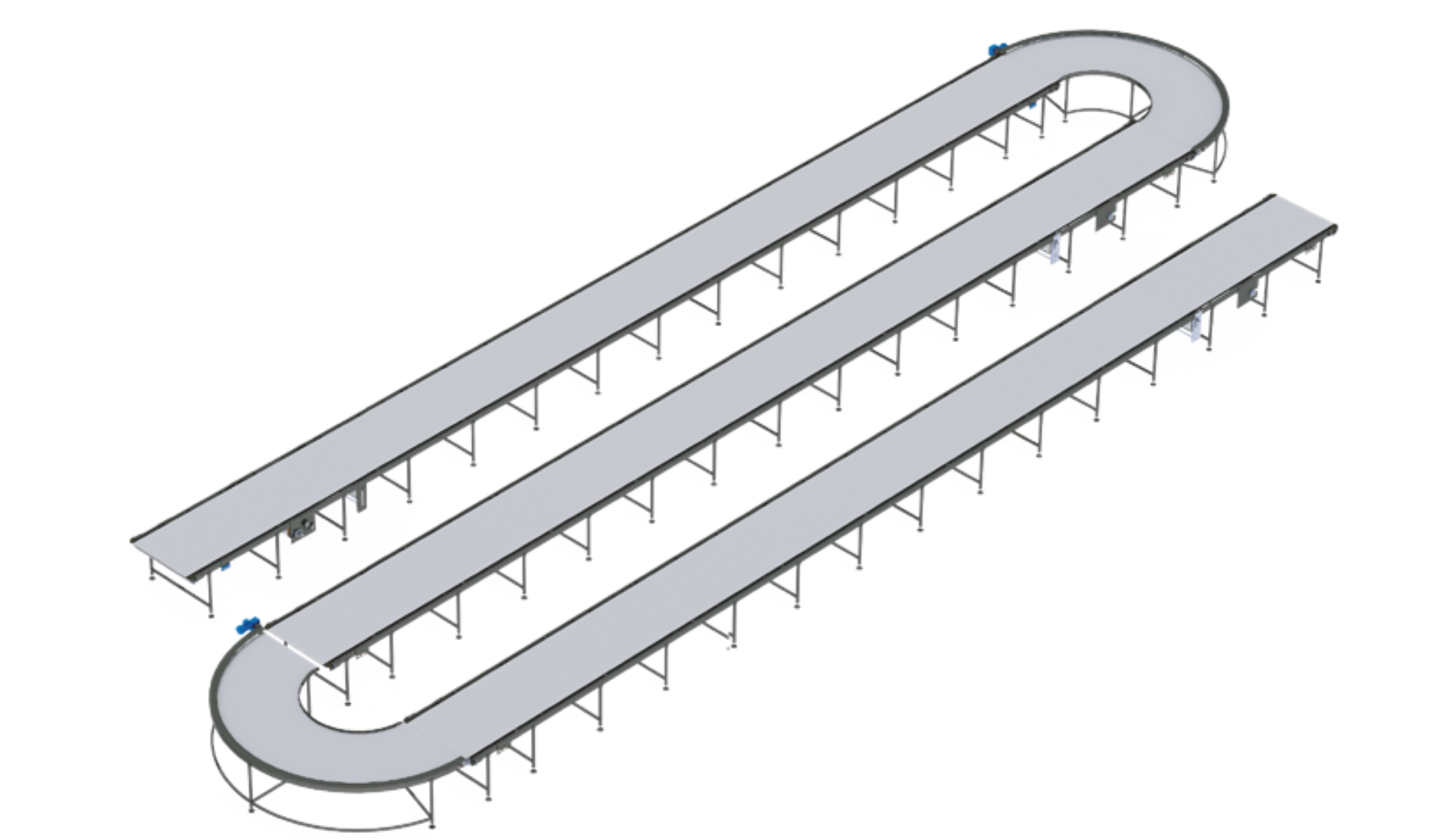

These are conveyors where cakes coming out of the oven are cooled. They may include some 90 degree and 180 degree turning band elements. They can be carried from the ceiling level when necessary. Some elements such as product flow rate, temperature at which it will enter the packaging or coating and production environment temperature are effective in its length. Depending on the product coming out of the oven, the cake should be left to cool for approximately 30 minutes.